| Background on U.S. Agriculture's Best Kept Secret The Soil Doctor® Application System |

|---|

| Take Me to

the SDr. System |

In 1986, they conducted their first on-the-go, real time, soil sensor tests and consulted with USDA experts in Beltsville, MD.

In 1987, Soil Doctor® Technology entered production agriculture with a Variable Rate Nitrogen Applicator which automatically responded to the real time sensor, foot-to-foot, and increased net profits by $10/acre. (Data recorded by John Deere's "Dirt Doctor", Terry Schneider. See December '96 "Furrow" magazine.)

And in 1990, Soil Doctor Highly Variable Rate Technology entered the U.S. market increasing net profits typically by $15 to $22/acre and currently as high as $50/acre, depending upon the operation itself and the weather, of course.

(To understand :Why doesn't everybody who is interested in variable rate technology, site specific farming, precision agriculture, etc. Know about CTI's incomparable expertise and success in these fields? See Whole Story or .

![]()

Application Demographics

The Only

$ECONOMIC$ Performance Guarantee in the Industry

| Integrating On the Go Soil Sensing (CEC, topsoil depth, and nitrate) into a Powerful, One-step tool, with which you can also Map, although mapping is not required, to Produce . . . . . . . . . . . . . . . . . . |

The Largest Array

of Technical Data, at the Finest Level of Field Detail, ----available in the World Today! |

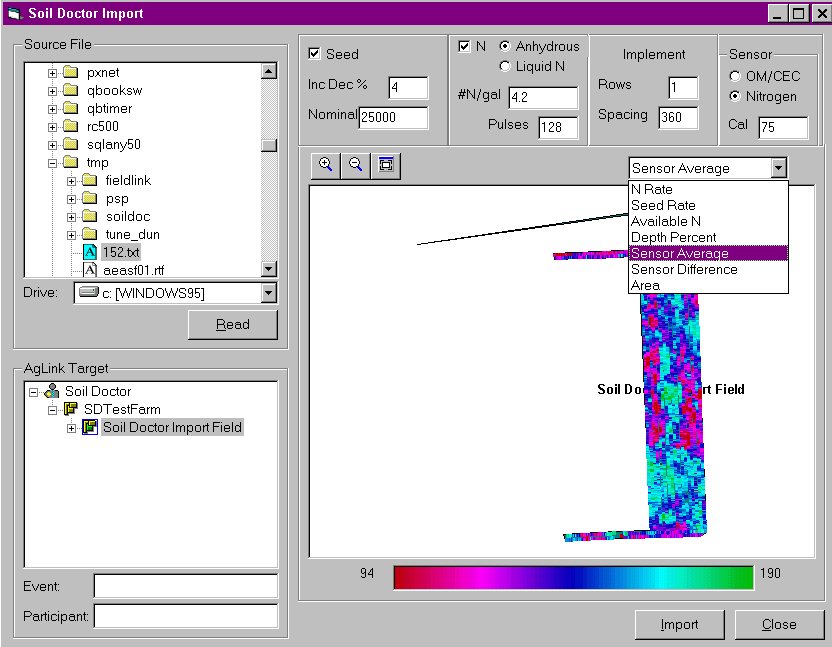

For a complete overview of the capabilities and use

of the Soil Doctor Plug-In,

download a copy [plugin.zip] for review.

The Most Complete "Picture" Imaginable Today

---of any Farm Operation---

CTI's

Soil Doctor® System

Utilizes Exclusive

Twin Parallel Processor Design

Get behind the Wheel of

An Anhydrous Tool bar, a VariPlant Planter, a VR Sprayer, a liquid Sidedress Bar,

or a LocalYield Monitor-equipped Combine.

And get more useful and usable information

than any other place on earth!

A Soil Doctor® System

at work in Western Indiana

Soil Doctor® RE/HR Systems use Standard Agricultural Coulters

as Paired Rolling Electrodes for the Sensing System

To Interrogate Continuous Soil Volumes (at 50 cubic yards/second).

Algorithms within the Field and Row Manager Units utilize these measurements to instantaneously apply nitrogen, seeds, other fertilizers, and crop protection chemicals. Although these algorithms are proprietary to CTI, the application technique for liquid/anhydrous products has been widely emulated since the Soil Doctor® System was first introduced to the public in 1987.

PWM Solenoid Valve Technology enables rapid delivery response to input commands. A Soil Doctor applicator uses a series of fast-acting solenoid valves (5ms rise time) mounted to a large manifold. Each valve is capable of a normal cycle of 5 times/second, but present Soil Doctor technology permits up to 30 cps cycling. Large, motorized ball valves cannot respond quickly to fine scale changes in demand without over or undershoot of the desired local application rate.

Applicator Kit (Including Manifold, PWM Valves, Liquid and Anhydrous Flow Meters)

Fidelity in delivery, in direct concert with intrinsic soil variations, is another central attribute of Soil Doctor technology. In the case of nitrogen management, soil nitrogen status beyond three feet from an individual plant simply has no affect on that plant. Hence, for optimal crop and groundwater performance, nitrogen must be examined and managed within this fine scale radius. If delivery is not accurately matched to local needs, typical of averaging assessments (e.g., regular grids), a prescription will not be delivered as intended, and the best results cannot be attained.

Normal prescription options include keying application uniformity across the implement based on either the minimum, maximum, or average nutrient level measured. Through additional software options available only to experienced owners, increased fidelity in each of three independent zones across the implement is available to address lateral variablility. With this option, each implement zone controls its own set of PWM delivery valves. Such flexibility is a valuable addition to operations where N fertility varies widely (e.g., honey wagons and/or injection).

Available Zone Control Option